The importance of industrial air filters for manufacturing

Mar 09, 2023|

Mar 09, 2023| View:333

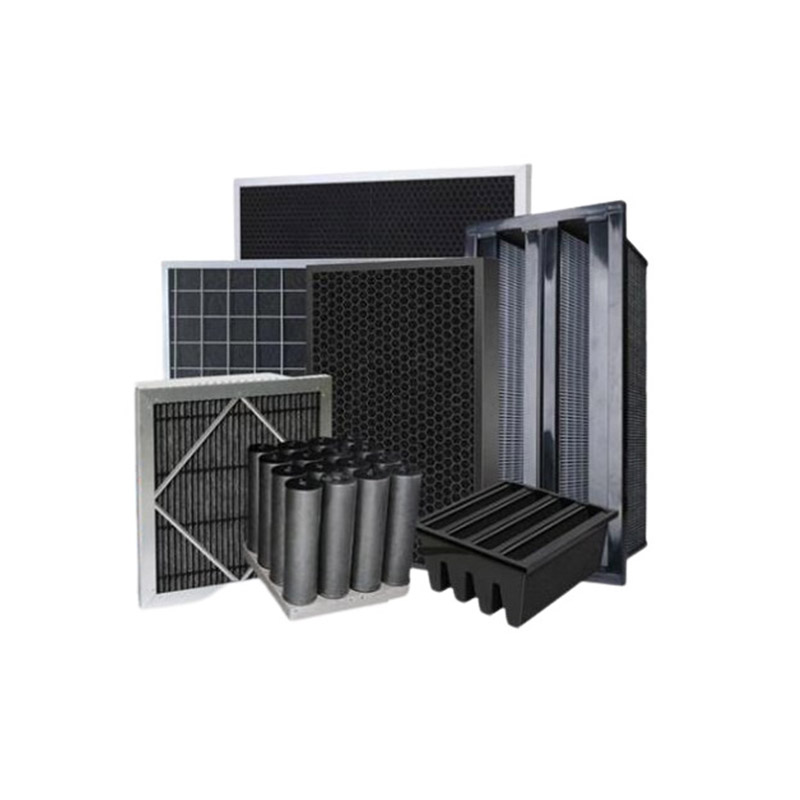

View:333From pharmaceutical to food processing to power generation industries, specialized equipment (vacuum pumps, blowers, compressors, generator sets, etc.) must be protected to ensure maximum uptime and high quality output, and industrial air filters were created for this purpose.

According to the Environmental Protection Agency, the air inside buildings and structures is typically two to five times more polluted than the air outside. Air pollution levels in industrial buildings can be even greater, especially for manufacturing plants or chemical processing facilities. In addition, residues from manufacturing processes, such as dust particles, oil mist aerosols and condensing vapors, can accumulate inside and outside of facilities, leading to process quality, equipment maintenance and workplace safety issues.

1. industrial air filters protect equipment from the ingestion of harmful contaminants.

The presence of contaminants in the manufacturing process can be extremely damaging to equipment, so one of the most important roles of industrial air filters is to capture and remove these contaminants and contain them for proper removal and disposal.

In more extreme applications, manufacturing processes can release dangerous aerosols and vapors, which can lead to vacuum pump failures - and even combustion events, depending on the compound. Therefore, industrial air filters must remove these harmful by-products in order to maintain proper equipment operation.

2. industrial air filters help remove contaminants to clean the air and airflow.

industrial air filters are critical in industrial manufacturing applications, including pneumatic conveying, additive manufacturing and landfill gas collection. It helps keep air and gas free of contaminants during operation and helps ensure the purity of the process output.

Air and gas filtration must be thorough and measurable to ensure the removal of harmful or unwanted contaminants. The output of many processes in industrial manufacturing must be clean and pure; any small change in contaminant levels can render the product unusable.

3. industrial air filters protect personnel and the work environment.

According to studies published by the U.S. National Library of Medicine and the National Institutes of Health, severe air pollution slows productivity and reduces output. Workers in industries with cleaner air quality have higher productivity levels. Therefore, installing proper industrial air filters is not only necessary to protect equipment, but is also essential for employee safety and productivity.

4. industrial air filters help separate and isolate the desired product from the air stream.

Many vacuum manufacturing processes require efficient separation of solids, liquids and vapors. This is not only to keep the system running properly, but also to capture valuable process output and minimize waste. This can be accomplished using special filtration and separation products/systems that separate products from the air/air stream under vacuum conditions. These specialized systems are used to separate specific vapors, fluids or solids from the air stream carried by the manufacturing process. For some industries, this is a critical part of the manufacturing process. For example, essential oil manufacturers must carefully extract and separate specific compounds under vacuum to create a usable product.

In summary, industrial air filters are necessary to capture common contaminants to help ensure product integrity and safety in the manufacturing environment. industrial air filters are also critical for protecting process equipment and maximizing uptime and performance.

This is all about the importance of industrial air filters to the manufacturing industry. If you need more detailed information, please feel free to contact us!

qr315@cooca.com.cn

qr315@cooca.com.cn